synchronous motor start.

Synchronous motor is basically an ac generator that works in reverse and built equal.They require dc excitation to the rotor pole and phase 3 supply to the stator.They do not start on their own, therefore require some means of running to accelerate before it can run at synchronous speed.

Two methods of starting that i know of are:-

1) to run the motor up to speed using a horse motor.

The horse motor drives the main motor to near synchronization. speed. the motor then needs to be synchronized with the supply

Dc excitation is then turned on, the rotor and stator fields are then locked and the horse motor is disconnected. the main motor then runs at synchronous speed, i.e not slipping.

2) to run up as an induction motor.

In this case, the copper rod is embedded on the surface of the rotor pole.

They short-circuited at each end, to form a grille, like a squirrel cage, but flat.

When the phase 3 supply is turned on, the motor runs as a normal squirrel cage induction motor.

At maximum speed, dc excitation is turned on and 2 locking fields to run at sync speed. embedded copper bars have no effect on synchronization. speed. ie not slip.

The main motor can be started using any conventional method.

Direct on line. for smaller motors.

Star-delta. for soft starting

Auto transformer start. for soft starting.

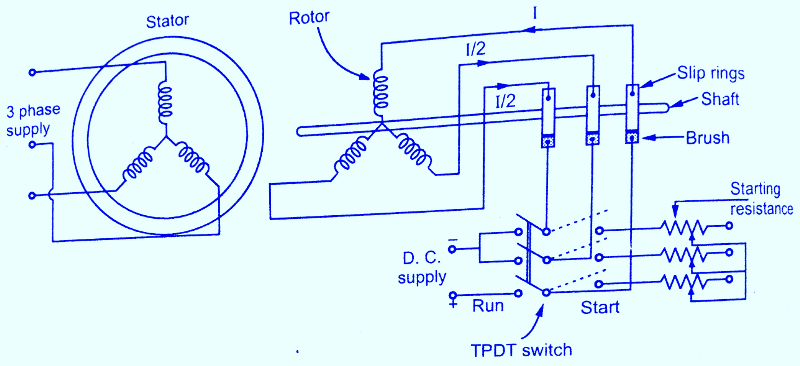

Dc excitation, variable, can be routed through 2-pole circuit breakers and corresponding slip rings.

The synchronous motor runs at only 1 speed.

Dc excitation varies to control (increase) the power factor of the entire plant.

Synchronous motor can not start by itself, due to rotor inertia. this makes the rotor inefficient to pursue a rotating magnetic field in synchronous speed. so, what is needed is a means to provide early torque so that the rotor can rotate and overcome inertia, where it can pursue a rotating magnetic field. this is achieved by one of the following approaches: –

Using another prime mover/motor to start the synchronous moto

1.Using a pony motor

Small induction motors (or other such motors, these motors are called horse motors) are used to start synchronous motors, so the synchronous motor starts running. after synchronous speed is reached, the pony motor is separated and the dc excitation is given to the rotor. as a dc excitation is given to the rotor now, it is locked with a rotating magnetic field, and moves in a synchronous velocity.

2. coupling a dc machine

Small dc engine coupled with synchronous motor. the dc engine is made to act as a dc motor so the synchronous motor starts. now, when the synchronous motor is made to run under synchronous speed, the dc engine will change the generator, whose dc output is used to generate the synchronous rotor field.